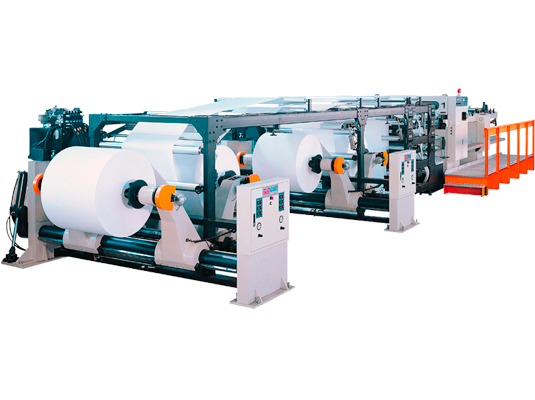

Guillotines sheeter machine Goodstrong SSCT-5-1320, 1600

Precise cutting of paper sheets on the roles of any desired format, including the loss of material in the waste that arise when working with ready-made "typical" sheet size.

GMC SSCT-5 - series sheeter machine with rotating upper and lower fixed blades. Designed for high-precision cutting of paper and cardboard. Depending on the type of material repulpable unwinding can be equipped with 2 or 4 to Rola.

Product details

Specifications

| Max. Web Width | 1600 ㎜ Trimmed | 63"' ㎜ Trimmed |

| Min. Web Width | 400 ㎜ | 15.7" |

| Max. Roll Diameter | 1800 ㎜ | 70.8" |

| Min. Roll Diameter | 400 ㎜ | 15.7 |

| Core Roll Diameter | 76.2 ㎜, 152.4㎜, 304.8㎜ | 3", 6", 12" |

| Cut-off Length Range | 460㎜ -1370㎜ | 18" - 54" |

| Max. Pile Height (including pallet) | 1200 ㎜ | 47" |

| Max. Pile Weight | 2000 kgs | 4,400 lbs |

| Max. Mechanical Speed (single web) | 300 MPM | 980 FPM |

| Practical production output is dependent on the quality and characteristics of materials, sheet size, number of rolls. Operator techniques and operating conditions. | ||

| Designed Knife Loading | 550 gsm | 550 gsm |

| Sheet Length Accuracy (single web) | ± 0.5 ㎜ up to 1000 ㎜ ± 0.05% over 1000 ㎜ | ± 0.02" |

| Sheet length Squareness (single web) | ± 0.5 ㎜ as measured for 1000㎜ wide sheet. | ± 0.02" |

| Main Power | 3 Phase, 220V, 50/60 HZ | |

| Total Power Consumption Required | 37 KW | |

| Machine Total Weight | 15000 kgs (1 roll stand) 21500 kgs (2 roll stand) | 33070 kgs (1 roll stand) 47400 kgs (2 roll stand) |

| Machine Dimension (L x W x H) | 15.5 x 5.8 x 2.5 M (1 roll stand) 20.8 x 5.8 x 2.5 M (2 roll stand) | 51' x 19' x 8' (1 roll stand) 68' x 19' x 8' (2 roll stand) |

A servo motor driving prodides high accuracy, high performance synchronous control system. ( + / -0.5 mm ) - ( 300M / Min )

Length of cut value is numerically entered for quick and easy size changing.

Various digital displays as length of cut, cut quantity, machine speed and cut speed.

The specially designed helical knife offers low cutting force, long service life, and high cutting accuracy.

Twin motor drive system.

Feeder roll and knife roll driven by separate AC servo motor systems.

Length of cut value is numerically enteredfor quick and easy size changing.

High speed outfeed tape section To accelerate the sheets away from the knives.

Fully synchronized speed between high speed outfeed and overlap tape section to maintain a proper shingle.

Exit Roller to the layboy with air jets to supply a curtain of air onto the underside of the sheets and assist delivery of the sheet into the pile.

Delivery table able to take 1200 mm pile height. Complete with automatic lowering from pre-set pile height sensor.

Pneumatic slitters ensure the stable andclean slitting.

Manually decurler adjusted through hand wheel.

Squareness adjusted manually per each job change.

Optional delivery top belt to assist in the operation for light weight paper

EPC Pneumatic sensor coupled with an independent "swing frame" allows for minimum edge trim of the web, and strict control of the web edge throughout the reel from start to finish.

Optional motor driven decurler with remote push button control.

Optional SIMCO HE Ionizing air nozzle to assist in the operation for light weight paper.

Dual position shaftless pivoting arm unwind stand with in-floor track and trolley system.

Air-cooled, pneumatically controlled brakes on each arm.

Auto tension control with swing arm dancer roller, gives constant full tension control from the start to the end of the reel.

_thumb1.jpeg)