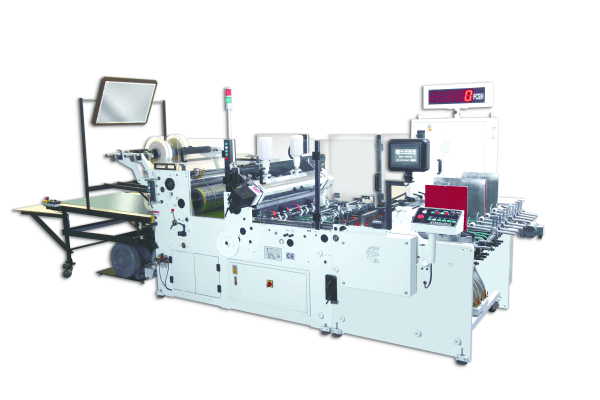

Servo Window Patching Machine Win Pack WPA - 1000 SV, WPA - 1000 DSV

- This machine has adopted 30mm thickness of main machine side frame that has a good effect for main machine of stability.

- In safety policies, this machine has been approved CE certificate. Therefore, no matter electric circuit and safe prevention. All of them follow CE specifications to design and manufacture. Those will let operators to get more protection.

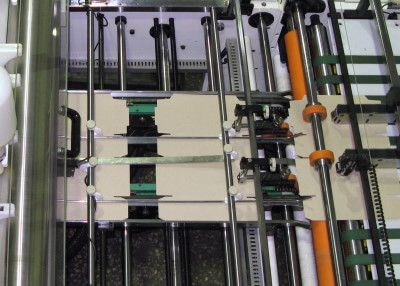

- The whole gluing device can pull the machine out and ease to clean gluing rollers and adjust the gluing stick shape position.

- The gluing rollers can adjust counter-clockwise, clockwise, left and right direction which let the gluing stick shape position register cardboard easily.

- The gluing device of delivery section consists of vacuum suction belts. It can ensure the cardboard of stability during delivery.

- 1R / 2R (Cardboard quantity for each cycle) option switch is on the control panel and you can change 1R or 2R by switch. It can save more time when you use it.

- The film patching wheel treats surface treatment precisely to avoid the scratch of film by friction.

Manufacturer Win Pack

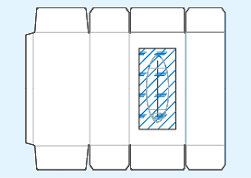

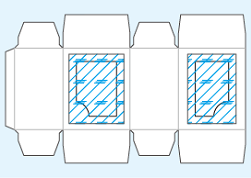

Product details

Feeder

- Servo Motor Drive timing belt feeding system will provide stable and high speed feeding.

- Easy set-up for the blank to synchronize to the touchscreen control system.

- Top load blank for non-stop feeding.

- Applicable to 250 g/㎡ up to E-flute corrugated cardboard.

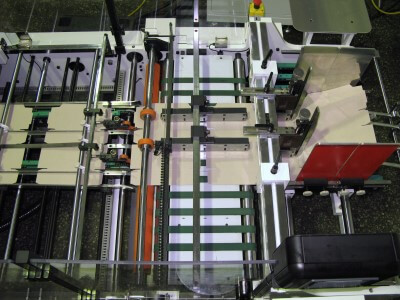

Positioning Device

- Easy set-up for blank position in a needing range.

- Delivery blanks in position by pushing block on the chain.

Glue system

- Automatic motor driven system for keeping glue roller turning while machine in stopped.

- Easy-Glue-Clean-Up-System is able to pull and slide out the whole glue system for clean up.

- Bottle Glue for changing and refilling easily.

- Standard suction belt to hold the blank in synchronize position while applying glue.

- Photo sensor detector automatically controls the glue roller to lift off when blank is not feed.

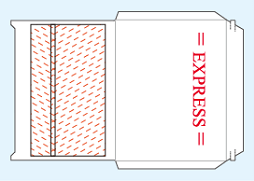

Film Section

- Rotary knife film cutting system for clean edge film cutting.

- Use suction cylinder to hold the cut film in position before applying the film onto blank.

- Easy adjusting handle for positioning the film to the blank.

- In order to reduce the film scratch which the suction cylinder made by finely process.

- Servo motor drive film cutting system in a needing length.

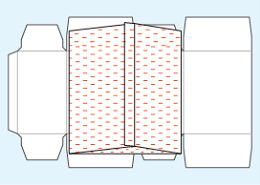

Delivery Section

- The blank will be transferred onto the delivery conveyor belt in overlap way.

- Motor drive conveyor belt to provide different speed for different blanks.

- Conveyor belt to timing speed up for showing fixed amount.

Specifications

| Model | WPA - 1000 SV | WPA - 1000 DSV |

|---|---|---|

| Blank length | 100mm ~ 710mm | 100mm ~ 710mm |

| Blank width | 80mm ~ 1000mm | 80mm ~ 480mm |

| Film length | 38mm ~ 520mm | 38mm ~ 520mm |

| Film width | 30mm ~ 840mm | 30mm ~ 400mm |

| Film thickness | 0.03mm~0.20mm ( Straight preparation ) | |

| Feed Material | Cardboard,E-flute Corrugated Cardboard | |

| Max.Working Speed (Length over then 330mm) | 150 sheets / min | 300 sheets / min |

| Max.Working Speed (Length less then 330mm) | 300 sheets / min | 600 sheets / min |

| Main motor (3.75KW) | Glue Wheel Motor | 40W |

| High speed blower (A) (3.75KW) | Air Compressor | 0.75KW |

| High speed blower (B) (1.5KW) | Feeder Servo Motor | 1.3KW |

| High speed blower (C) (0.75KW) | Feeder Servo Motor (DSV) | 1.8KW |

| Vibrating Motor (0.05KW) | Film Servo Motor | 0.9KW |

| Conveyor Motor (0.2KW) | Total Power Requirement | 12.99KW / 14.79KW |

Contact form