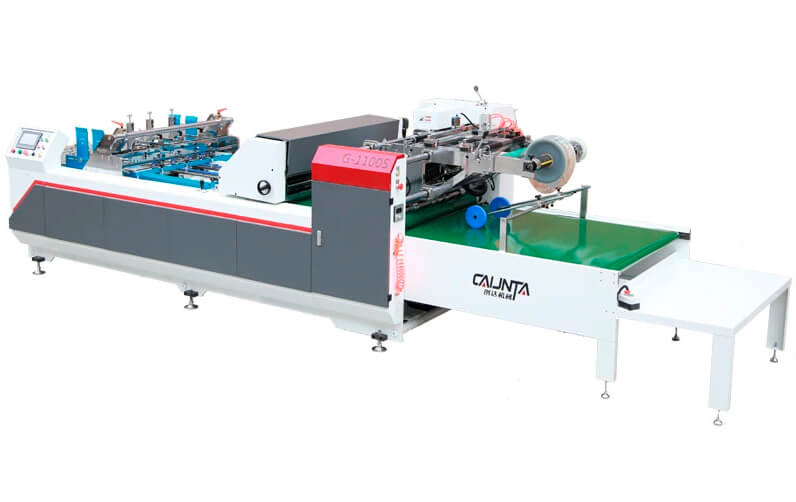

Full-Automatic Universal Window Patching Machine Caunta TC-1100A

TC-1100A full-automatic universal window patching machine is an economical and practical model. The film cutting adopts a horizontal knife with high cutting accuracy. And the thickest can be cut 0.3mm thick PET film, with film creasing, angle cutting, hole punching and marking functions, and with printing film tracking function.The machine adopts servo motor to control the paper feeding and film feeding separately, and the stepper motor to drive the back belt independently. It can adjust the distance between paper folding and count in batches.The paper conveying belt of the machine adopts vacuum absorbed. It has automatic lifting function in coating section when short of paper. It can mark and cut the printed film. It can also be extra equipped with tissue box cutter device. The machine runs steadily at high speed and is easy to adjust.It can adjust the film length and left& right film position without stopping. The machine is controlled by PLC computer with high precision, maintenance-free and abnormal operation protection features. It is suitable for local gluing and pasting of cardboard and corrugated paper and applicable for PE, PVC, PET, BOPP, APET and other film.

Product details

Specifications

| Model | TC-1100A |

|---|---|

| Max.Paper Size | W1100mmXL800mm |

| Mini.Paper Size | 110mmX110mm |

| Paper gram above | 250-1000g/㎡ |

| Max.Film | W500×L400mm |

| Mini.Film | W50×L60mm |

| Film Thickness | 0.06-0.25mm |

| Max.FilmUnwinding Diameter | 400mm |

| Paste error | ±1mm |

| Working Speed | 4000-8000pcs/h |

| Power | 380V 50Hz 9KW |

| Machine Size | L550cm×W170cm×160cm |

| Overall Weight | 3200KG |

| Servo Motor | 2 SETS |

| Stepping Motor | 1 SET |

| Asynchronous Motor | 2 SETS |

| Dimension of V-shaped punching mould | 26mm |

| Quantity of V-shaped punching mould | 2PCS |

| Quantity of film creasing wheels | 2PCS |