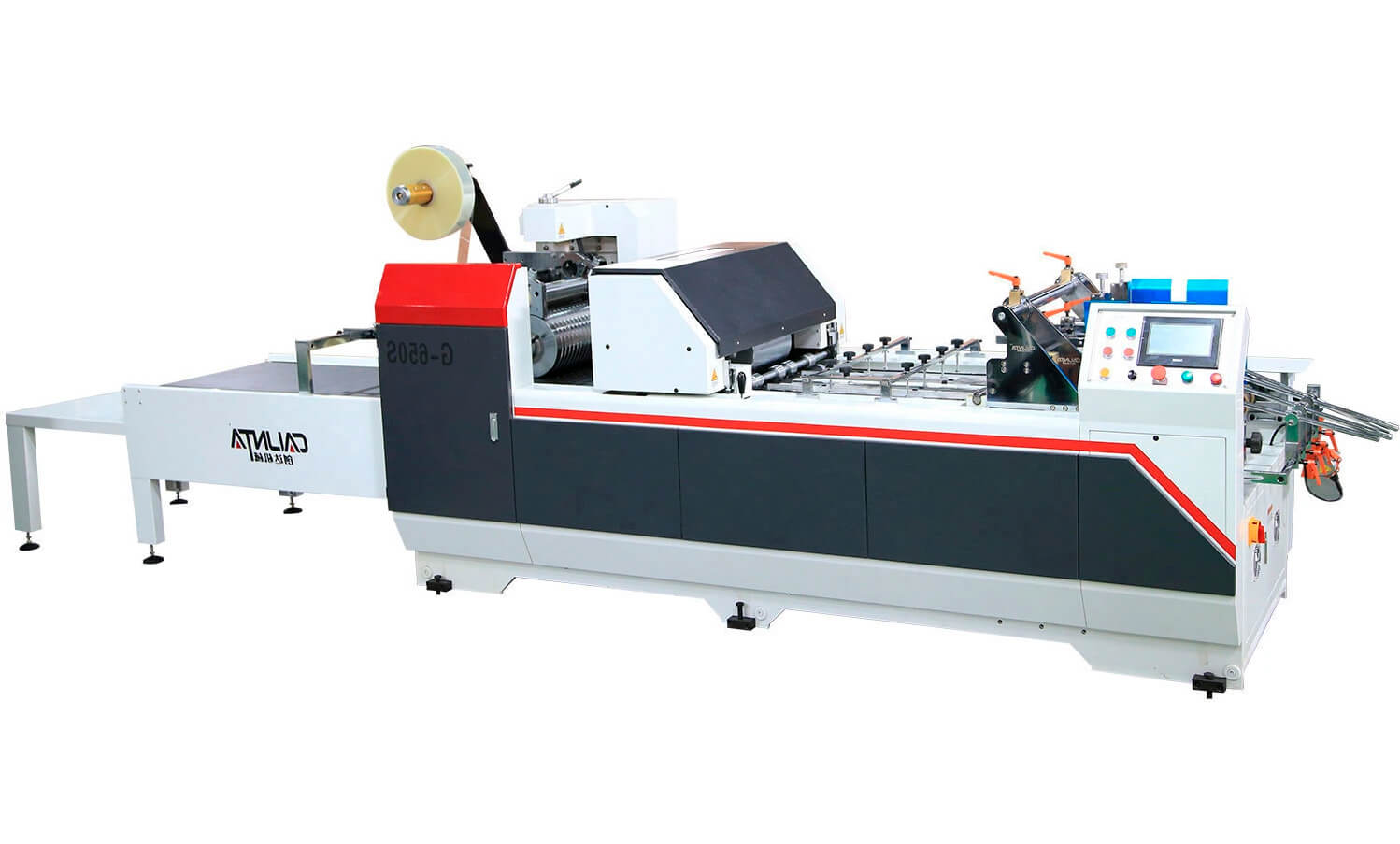

Full-Automatic High-Speed Window Patching Machine Caunta G-650/650S/860S

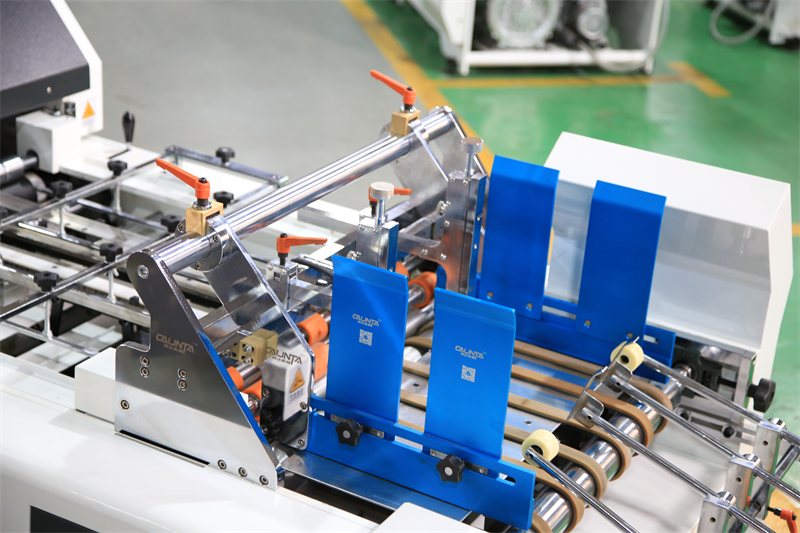

- Hob cutting film + Single group film applicator

- Servo motor paper feeding

- Servo motor film feeding

- Paper receiving stepper with batch counting

- Paper vacuum adsorption transport

- Double sheet / empty sheet gluing rising automatically

- Paper length L < 260mm double sheet mode

- Follow lable of film printing surface(optional)

- Film with punching holes (optional)

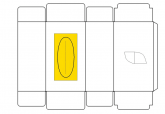

- Tissue box film middle cut (optional)

Product details

Specifications

| Model | G-650 | G-650S | G-860S |

|---|---|---|---|

| Max.Paper Size | W650xL550mm | W650xL550mm | W850xL550mm |

| Mini.Paper Size | 110x110mm | 110x110mm | 110x110mm |

| Paper gram above | Kraft Paper:150-1200g/㎡ White Cardboard:230-1200g/㎡ Corrugated Paper:≤3mm | ||

| Max.Film | W290xL300mm | W290xL300mm | W290xL300mm |

| Mini.Film | W30xL50mm | W30xL50mm | W30xL50mm |

| Film Thickness | CPE/PE:0.1-0.3mm PVC:0.08-0.25mm APET/PET:0.06-0.2mm | CPE/PE:0.1-0.2mm PVC:0.08-0.20mm APET/PET:0.06-0.18mm | |

| Max.Film Unwinding Diameter | 400mm | 400mm | 400mm |

| Paste error | ±2mm | ±2mm | ±2mm |

| Maximum Speed | 15000pcs/h | Paper L≤260mm:30000pcs/hPaper L>260mm:15000pcs/h | Paper L≤260mm:30000pcs/h Paper L>260mm:15000pcs/h |

| Servo Motor | Driving part:Paper feeding department 1 set ,film delivery department 1 set | ||

| Stepping Motor | Driving Parts: Automatic paper receiving 1 set | ||

| Machine Size | L540xW130x160cm | L540xW130x160cm | L500xW150x160cm |

| Power | 380/415V 50/60Hz 5KW | 380/415V 50/60Hz 5KW | 380/415V 50/60Hz 6KW |

| Overall Weight | 1720kg | 1800kg | 1800kg |

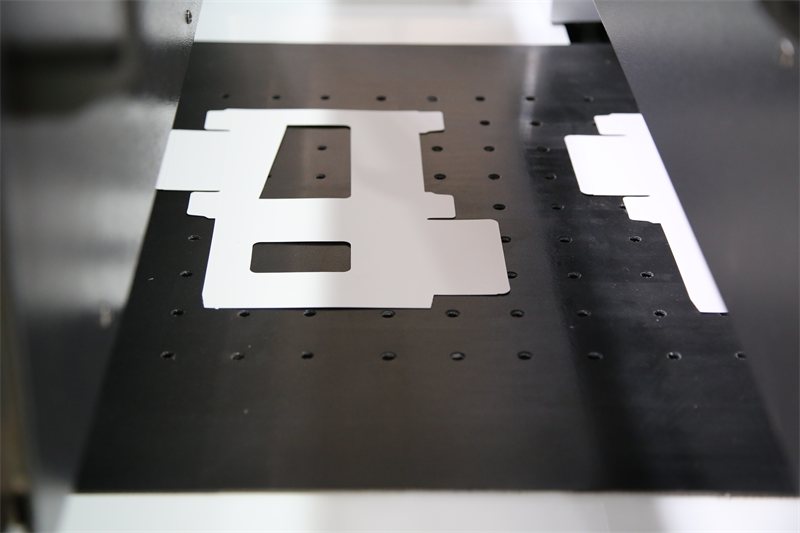

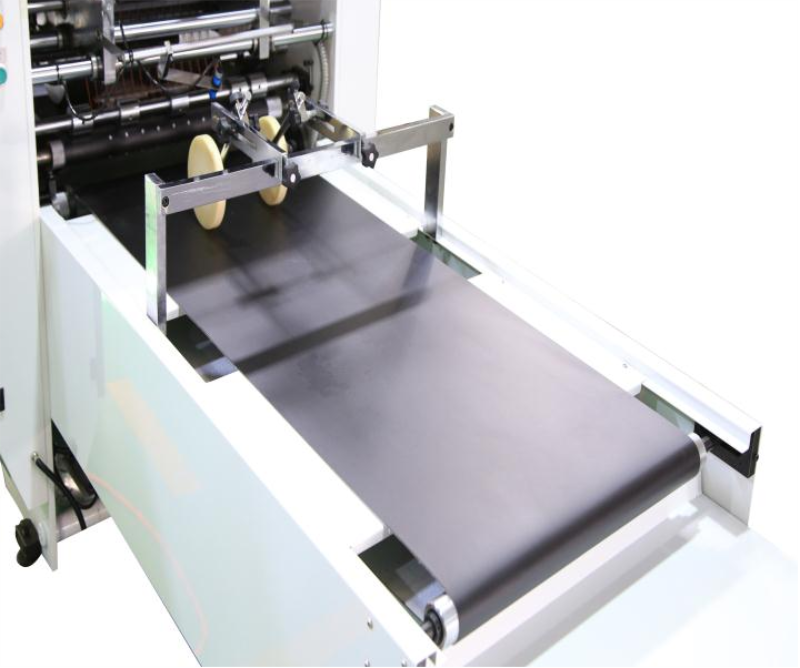

Adopt belt feeding paper ,it is suitable for coated, reverse UV, nano UV, oily and waterborne paper, kraft paper and corrugated paper.

All the parameters and functions of the switch are operated in the touch screen, and the operation panel is equipped with a "Inch, start, stop, speed adjust" quick operation button.

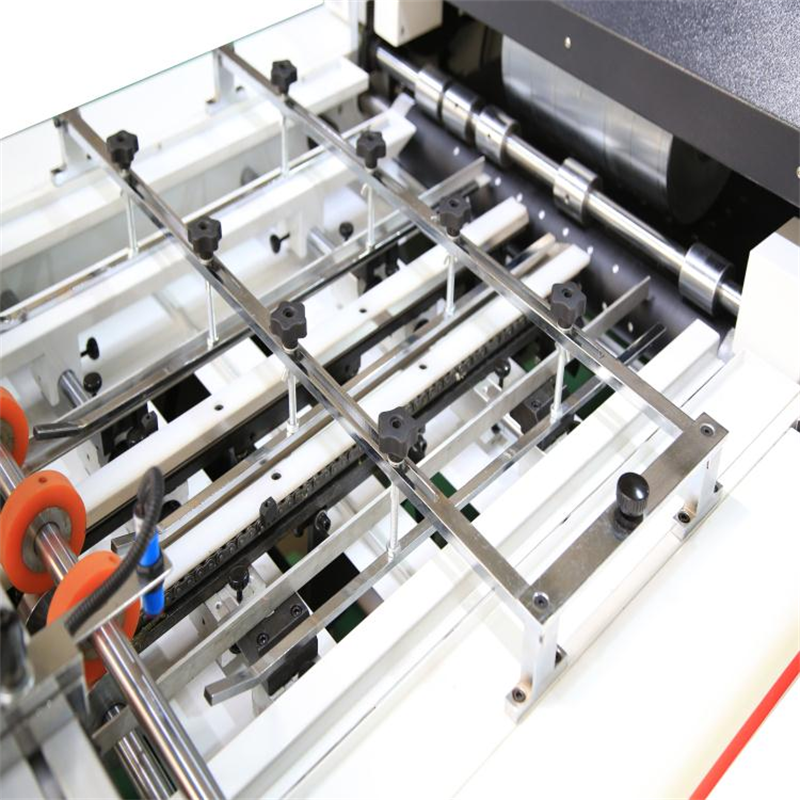

Chain guides are made of imported polymer materials, wear-resistant and mute, and paper positioning is made of square pushers to increase the stability of paper in high-speed operation.

Paper is vacuum absorbed by perforated belt in the whole process of gluing and pasting.It runs steadily at high speed and has high precision.

Single stepper motor controls the operation of paper-collecting belt. Paper-folding distance can be adjusted wholly or segmentally and run at multi-speed.

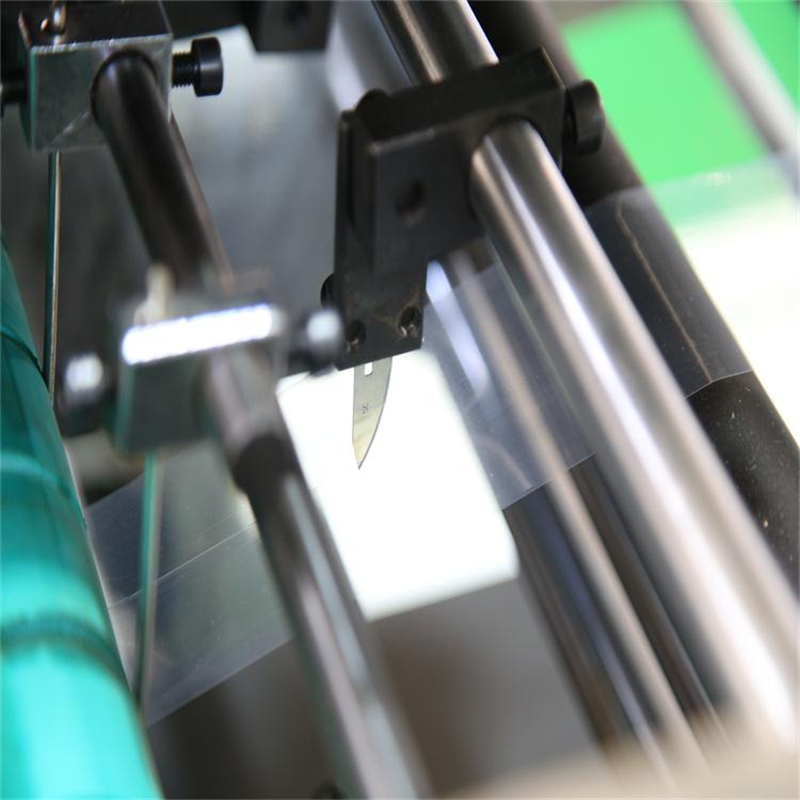

Film cutting hob is a local sectional design. Compared with traditional whole section cutting, it has lower noise, less vibration, more convenient tool adjustment and tool change. Adding back spring prevents the occurrence of stuck knife problem.

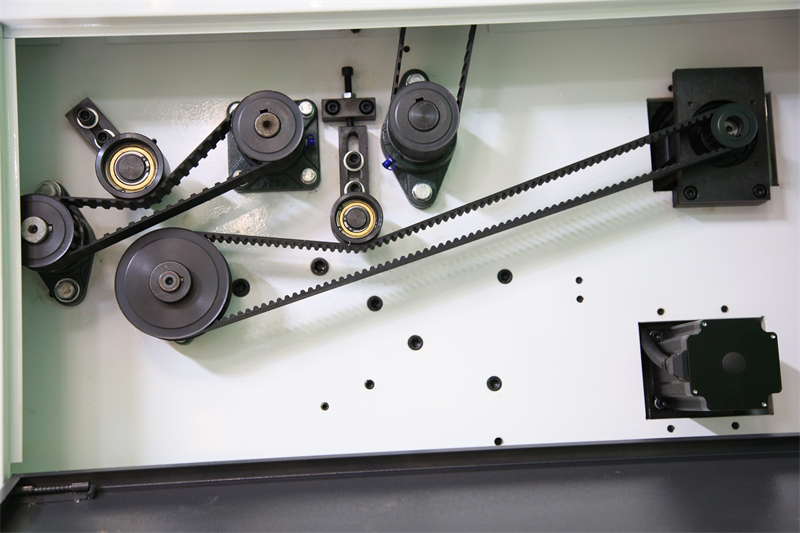

All drives are driven by synchronous wheels and synchronous belts with low mechanical noise and high accuracy.

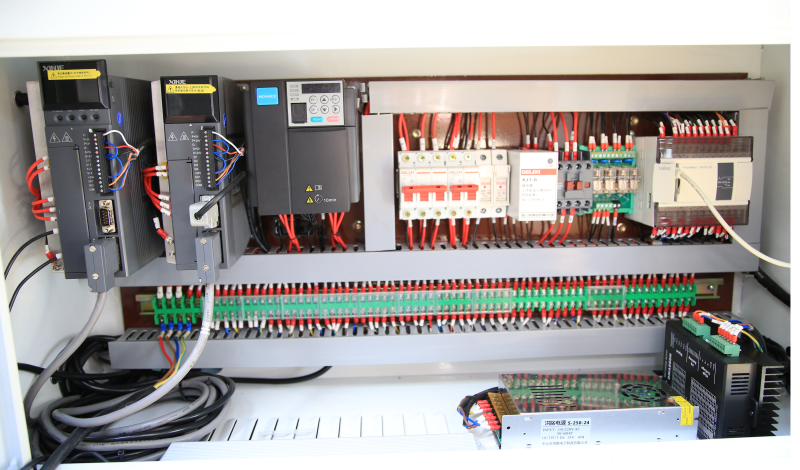

Adopting domestic listed companies' first-line brand "Xinjie" servo drive system and "lnovance" frequency conversion speed regulation system, the stability is high.

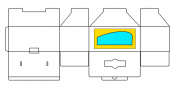

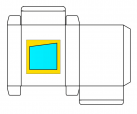

1. Paper towel box film opening device can be installed to open or cut off the local film.

2. A cursor tracking system for film printing can be installed to track and locate the pattern of film printing surface, and the position of window and film pattern sticking is always the same.