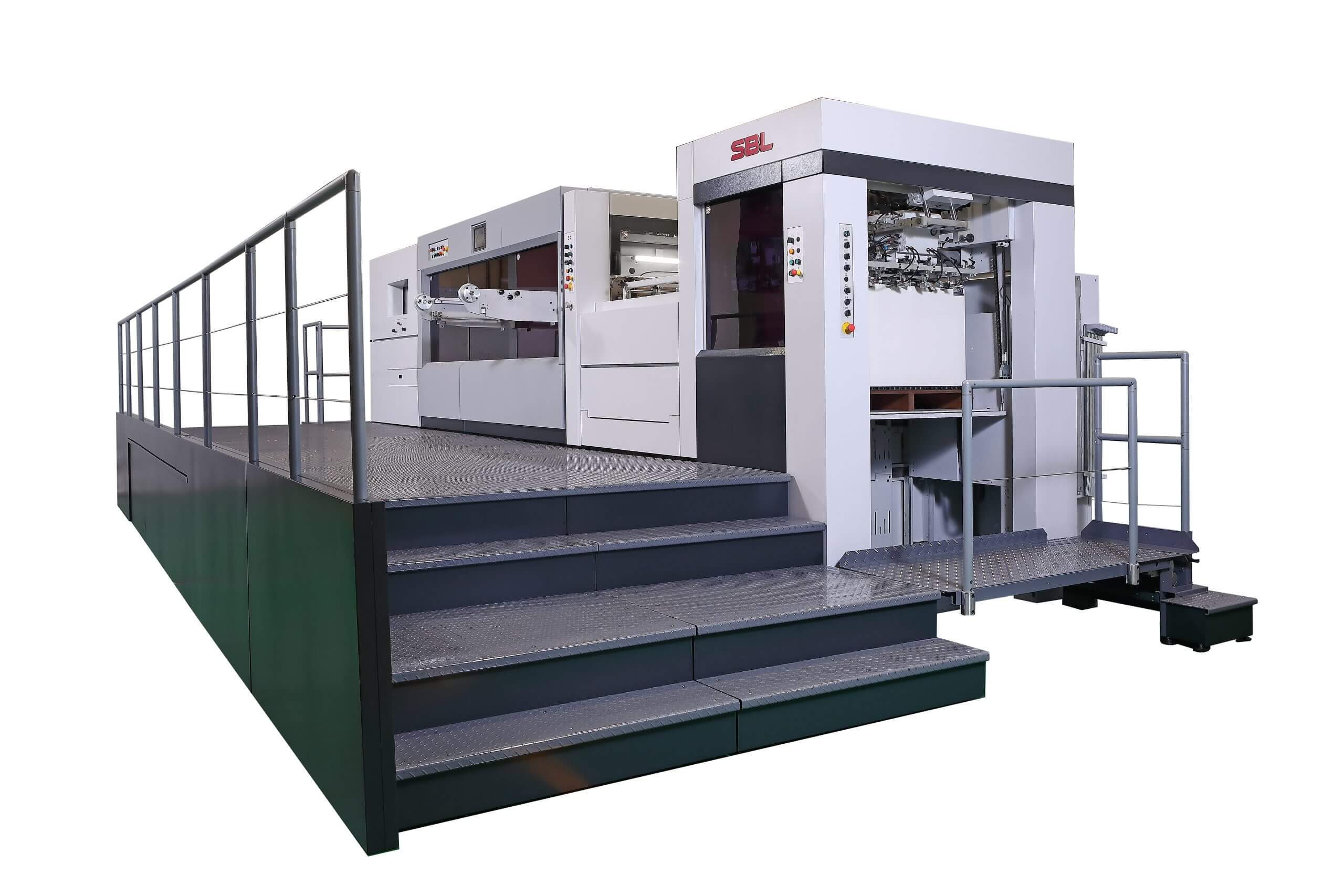

Automatic Diecutting and Creasing Platen with Stripping and Blanking SBL Group 1060SCB

-

Manufacturer SBL Group

Product details

Efficient and Flexible

- Cutting, stripping, blanking in one pass for up to 9,000 sheets/hour

- Synchronized feeder and register provide extremely accurate non-stop feeding

- High flexibility for short-run jobs, non-stop production for long –run jobs

Hassle-free blanks ready for the next step

- Amazing blank quality, ready for next step

- Automatic sheet inserter, delivering perfect blank piles

Cost-effective design

- Minimizing operator intervention and maximizing uptime by high automation

- Easy accessibility, fast setting and changeovers for optimal productivity

Intelligent Feeder

- Motorized side adjustment of Pallet table (+/-35mm), ensuring precise feeding

- Non-stop system for Feeder Section

- Movable gangway puts adjustment elements within easy reach

- Continuous and stable sheet feeding with perfect material positioning enable to run various weight of stocks precisely

- Auxiliary air blower can be adapted from thin material to cardboard

Feed Table Register

- Front lays register device with 4 sensors brings each sheet into perfect cut-to-print register

- Optical lateral sheet register: Lateral sensors identify

- Sheet edge for automatic centering

- Ultrasonic double sheet detector without making contact with jobs leading to scratch free

Die Cutting Section

- Double cam drive system conveying sheets in the smoothest way possible

- FCD 600 high rigidity platen with 4 ways +/- 0.9mm micro adjustment

- Motorized adjustment of cutting pressure up to 260 tons

- 2 quick lock die-cutting chases for quick and easy setting which are locked and pushed by pneumatic system

State-Of-Art Gripper Bar

- 8 pieces of state-of-art gripper bar from SBL latest technology, which allows minimum number and size of nicks at reasonable maximum production speed due to the unique design of large-motion

- Angle eccentric worm gear drive system

- Carbon fiber gripper bar, lightweight in design & high rigidity for enduring performance

- Access to sample sheet with gripper opener using pneumatic at Stripping Section

In-Line Stripping Section

- Upper frame with quick lock mechanism

- Center line and register system for stripping

Blanking & Blank Pile Delivery

- Upper frame with quick lock mechanism

- Center line and register system for blanking

- Automatic sheet inserter

- Automatic non-stop rack for continuous production -Air sheet braking unit /sheet tail suction device increases the stability of the sheet movement and allows smooth transfer

- Automatic non-stop rack for continuous production

- In-ground conveyor for efficient operation

Specifications

| Model | 1060SCB |

|---|---|

| Max. paper size | 1060 x 760 mm |

| Min. paper size | 400 x 350 mm |

| Max. die-cutting paper size | 1060 x 746 mm |

| Maximum cutting pressure | 260 Tons |

| Thickness of die-cutting paper | 0.1~2.0 mm |

| Corrugated paper | E flute (≦ 2mm) |

| Max pile height at feeder | |

| (Without /With non-stop ) | 1820 / 1520 mm |

| Max pile height at finish with non-stop | 1550 mm |

| Width of Gripper margin | 9 ~ 17mm |

| Outside size of die chase | 1190 x 880 mm |

| Inner size of die chase | |

| 1080 x 770 mm | |

| Plywood Max. of die | 1070 x 725 mm |

| First Cutting Rule | 13mm |

| Size of counter plate (cutting plate) | 1090 x 760 mm |

| Height of cutting rules | 23.8 mm |

| Stroke of moveable platen | 44 mm |

| Accuracy of die cutting sheets | ±0.075mm |

| Maximum punching speed | 9000 Sheets / hour |

| Power Required | 43KVA (34.4KW) |

| Machine Dimension (with catwalk) | L 9718 x W 6236 x H 3145 mm |

| Machine net weight | 23 Tons |

Contact form