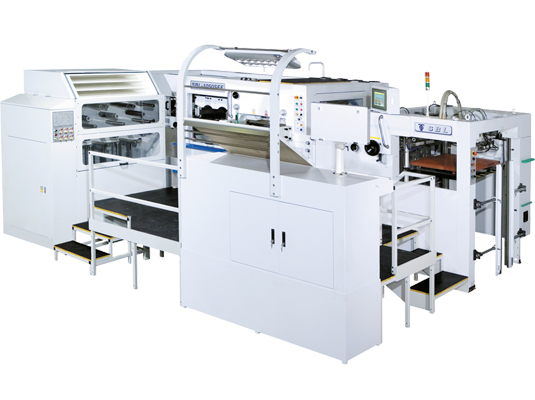

Automatic foil stamping and diecutting platen SBL 1300EF

1 Computerized foil feeding system with 3 foil control shafts to precisely control the foil length as desired.

2 18 zones heating system with precise temperature controller can be set individually.

3 Automatic pressure on/off system with tonnage searching program pre-set at low tonnage to avoid damaging die and machine.

4 Pneumatic honeycomb and chase locking system to eliminate loose mechanical parts.

5 LCD Digital display indicates the correct side guide at 90° angle to the front lay.

6 Non-stop device for feeder and delivery station can ensure continuing production.

7 Touch screen monitor with computerized self-diagnostic system is easy to operate and helpful for troubleshooting on each section.

8 Cutting pressure can be adjusted according to the stocks and the maximum pressure can up to 500 ton.

9 Recycling oil temperature controller to maintain an even cutting pressure.

10 Special brush push down device and joggle device at delivery station to ensures proper stacking.

11 Various stock cutting range from light paper to B-flute.

Product details

Specifications

| Model | SBL-1300EF |

|---|---|

| Max. paper size | 1300mm × 950mm |

| Min. paper size | 600mm × 450mm |

| Max. die-cutting paper size | 1290mm × 940mm |

| Min. gripper margin | 9.5mm |

| Die-cutting force | 500 Tons |

| Inner size of die chase | 1420mm × 958mm |

| Cutting plate size | 1328mm × 940mm |

| Range of material thickness | 0.1mm~2mm (80~1400gsm) |

| Corrugated paper | ≦4mm |

| Height of cutting rules | 23.6mm |

| Max. punching speed | 6000S/H |

| Register tolerance | ±0.075mm |

| Main power | 30KVA |

| Feeder pile height with pallet | 1200mm |

| Feeder pile height with pallet (without non-stop) | 1400mm |

| Delivery pile height | 1040mm |

| Small sheet device (option) | – |

| Longitudinal puller shafts(optional) | 2 (3) |

| Transeversal puller shafts | – |

| Max. foil diameter | φ200mm |

| Rewind shafts | 8 |

| Max. rewind diameter | φ400mm |

| Max. stamp speed | 6000S/H |

| Heating zones | 18zones |

| Hot foil stamping power | 40KVA |

| Outer size of machine(mm) | 6769L × 2444W × 2244H |

| Machine weight (approx.) | 26Tons |