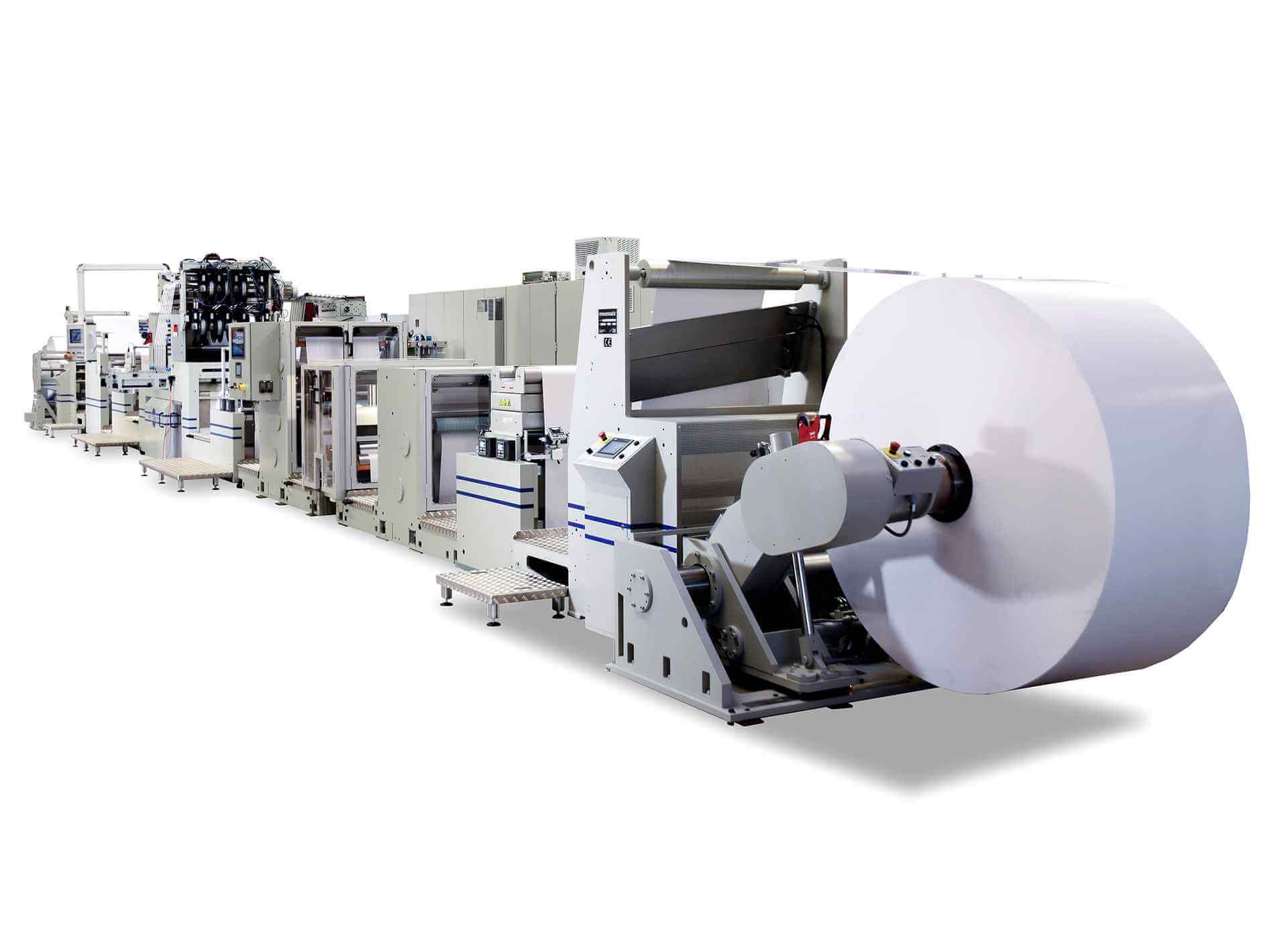

Flexible foil stamping machine Gietz ROFO 910 PLUS

Due to its flatbed stamping printing principle the ROFO 910 PLUS is able to process a wide range of substrates (paper, cardboard, plastic film and composites) whilst ensuring the highest quality standards in hot foil stamping, embossing and hologram application.

Manufacturer Gietz

Product details

Benefits

- Web speed up to 130 m/min

- High performance foil transportation system VACUFOIL

- Dwell time

- Efficiency

- Longitudinal and transverse foil feed

- Up to 11 foil webs

- Modular system

- Hologram application technology

Specifications

VACUFOIL

- Longitudinal or transverse foiling operation

- Suction channel frames with loop sensors to house the foil before pulling

- Suction board at press entry for foil web tension control

- Pneumatic vacuum device at press exit with adjustable blowing nozzles for foil separation

- Air cushion shafts to better support the foil travel

- Air induced draft fans with aspiration pipes to generate the vacuum

Machine extensions

The standard machine can be extended by a second stamping station for hot foil stamping and blind embossing. Another possibility is to add a web sheeter or different substrate un- and rewind solutions as well as other machine components.

Visualisation and inspection equipment

- A single camera video system for print quality monitoring can be supplied

- For inspection and observation of the quality of high gloss reflecting foil stamped areas, a state of the art system for fault detection based on incremental reading is available. This works also for hologram application in security applications

Baling press for foil waste

- High capacity baling press for waste foil

- The foil waste drive is located outside the machine, offering a clean and time saving solution

Hologram application

- The hologram foil is unwound using the VACUFOIL foil transportation system

- The foil tension of each hologram foil web is individually adjustable

- The register mark detection happens inside the press or at the entry to the press

Contact form