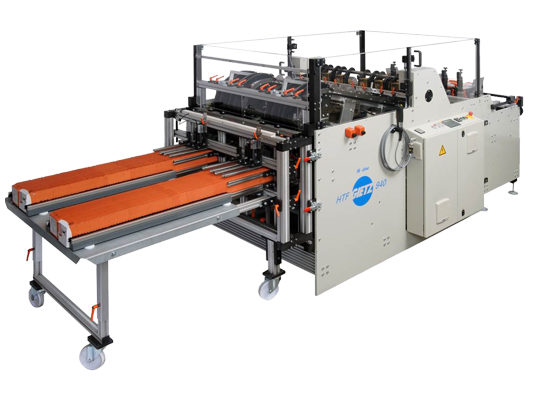

Erecting and gluing machine for conical trays made of cardboard and corrugated board Gietz HTF 940, 1270

The best in tray forming

The HTF machine range is designed for the gluing and forming of conical trays. Printed blanks are glued and formed to trays with or without cover lids, take-away boxes or hamburger clamshells. The HTF coverts all common types of cardboard / corrugated board.

Product details

Specifications

| Model | HTF 940 | HTF 1270 |

|---|---|---|

Speed max. | 12'000 strokes/hour/stream | 12'000 strokes/hour/stream |

Cardboard min. Cardboard max. | 180 gsm 600 gsm | 180 gsm 600 gsm |

Corrugated board | E/F/N | E/F/N |

Size of blanks max. 1-stream operation

|

940 x 500 mm / 420 x 500 mm / 250 x 500 mm /

|

1270 x 500 mm / 590 x 500 mm / 360 x 500 mm / 250 x 500 mm / |

Size of blanks min. | 100 x 100 mm / | 100 x 100 mm / |

Container depth min. | approx. 15 mm / 0.6" | approx. 15 mm / 0.6" |

Container depth max. | approx. 320 mm / 12.6" | approx. 320 mm / 12.6" |

Container side angle min./max. | 5 ° - 50 ° | 5 ° - 50 ° |

Weight | approx. 1.9 t/4188 lbs | approx. 2.2 t/4850 lbs |

Base area | approx. 4.20 x 1.50 m / | approx. 4.20 x 1.80 m / |

Many decades of experience in the construction of tray forming machines combined with practical knowledge from the customers allow Gietz to offer a range of highly productive and versatile machines that can be upgraded and retrofit at any time. The user benefits from a long-lasting and efficient machine concept.

The 10 Advantages

1. Up to 12'000 trays per hour and stream

This highly productive machine can convert blanks with up to 12'000 strokes per hour and stream.

2. Modularly retrofittable machine

Even if the machine is originally equipped for one-stream operation only, further streams can be added later at any time. The HTF can be retrofitted with further options such as a flanging station or plasma nozzles for the pre-treatment of coated gluing flaps.

3. High production security at the in-feed units

The pneumatically controlled in-feed of the blanks guarantees highest reliability and production security.

4. A selection of gluing systems

Whether a 2-/4-/6- or 8-point gluing is required, the HTF offers users a complete choice of gluing systems to suit different applications. The machine can be equipped with a unit for cold gluing by soft pads, a cold gluing unit with spray nozzles or a hot-melt adhesive unit with spray nozzles.

5. Intelligent movement of forming dies

Various parameters such as the start, end, length and speed of the forming stroke can be selected to guarantee optional production security. For an optimum folding procedure of hamburger clamshells a pair of twin swords is integrated in the movement.

6. User-friendliness

The swing away delivery allows easy access and a quick and comfortable setup of the forming stations. The horizontal delivery of the trays at optimal working height simplifies the removal of the finished cartons during production.

7. Short setup times

For all tray types a fix forming station is available with the corresponding forming dies. In just a few steps, these fix forming stations can be fitted to the machine, which dramatically reduces the makeready times. All fix forming stations are set, tested and adjusted upfront at supplier site.

8. Core competence and durability

Since 1968, the Gietz company manufactures machines for the forming and gluing of conical trays. This know-how combined with the practical experience made by hundreds of machine users is incorporated into the HTF technology. In addition the very solid and robust machine construction guarantees long durability.

9. Price/performance ratio

Best quality of forming and gluing systems, maximum production speed and security, as well as a durable construction: a Gietz machine is well worth its price.

10. Industry leading products for professionals

Machines for the forming and gluing of conical trays from Gietz are recognized by the paper converting industry worldwide as leading products from professionals for professionals.