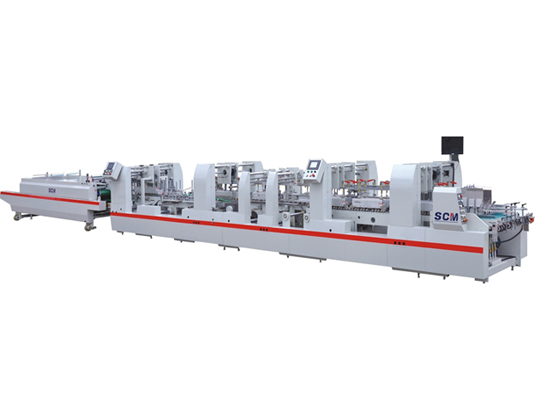

High-speed automatic folder gluer SCM SQ-850, SQ-1100,SQ-1250,SQ-1450

Most productive and flexible

max speed upto 600m/min

Product details

Specifications

| Модели | 850 | 1100 | 1250 | 1450 |

|---|---|---|---|---|

| Paper Range | max. 800gsm cardboard; E,B flute corrugated board | |||

| Speed Range | max. 300-450m/min | |||

| Glue | emulsion type | |||

| Box Type | straight line; double wall; lock-bottom; optional 4 or 6 corner collapsible box; | |||

| Main Power | 17kw; 19.5kw; 20kw; 22kw | |||

| Weight | 7800kgs; 8200kgs; 8600kgs; 9200kgs | |||

Feeder section:

Eight individual adjustable feed belts to ensure easy setup and smooth feeding.

Designated A/C motor with micro-adjustable variable speed controller for even spacing of box blanks.

Pneumatic lift-up side plates and feeding gates for easy operation.

Feeder start/stop can be controlled by remote controller at any operation area.

Feeding belt with angle adjustable cleaning brush increase belt friction for smooth feeding.

Mechanical vibration system with supporting bars for smooth and consistent feeding.

Optional: Suction feeding system.

Pre-breaking section:

Three carriers throughout with pre-breaking sword (180°) on the left side and belt pre-break device (135°) on right side enable the pre-fold of the 1st and 3rd crease lines to make final automatic filling much easier.

Sectional upper carrier combined with special design can be telescopically adjusted, no need to tension the belts, quick set up and job change over.

Optional: Plasma surface treatment system or UV grinder with air blower system.

Lock bottom section:

Three-carrier construction with split upper carriers.

Sectional upper carrier has the same design function as the one in pre-breaking section, suitable for make special shape boxes.

Easy for mounting lock bottom accessories, more operator friendly.

The hookers with high steel springs are excellent and stable for high speed operation.

Gluing section:

Lower gluing wheel by 2-section doctor blade to control the gluing volume, avoid splashing at high speed production.

Standard two Lower glue tanks, easy to remove and adding emulsion cold glue, clean and fix.

Can be customized with two upper glue tanks as standard according to customer request.

Optional: Electronic high-pressure cold glue spaying system for lock-bottom boxes, special shape boxes or small boxes.

Folding section:

Three-belt carriers

Upper carrier can be adjust forward or backward, easy for special shape boxes with optional devices.

Optional: small boxes attachment, based on changing to one-belt carrier.

Trombone section:

Equipped with the electronic sensor to coordinate the conveyor to match the main machine speed for perfect collection.

High-speed counter with kicker or spraying gun.

Jam detector as standard.

Conveyor section:

Two operation modes for compressing the folded boxes:

Auto - belt speed depending on machine speed: box flow without spacing

Manual - belt runs at a constant speed

Extra sponge belt for positive pressing at lower area of the box

Pneumatic controlled pressure easy to be regulated vertically, which increase the gluing effect.

Main parts list of SQ series folder gluers

All electrical components including PLC, touch screen, frequency inverter, AC driver, contactor, relays and buttons are from Schneider

Main driving motor is from ABB

Power switch is from SIMENS

All ball bearings are from IBC;All drive bearings are from TIMKEN

All belts are from Swiss HABASIT,German Optibelt, US Gates

Servo motors are from Rexroth.