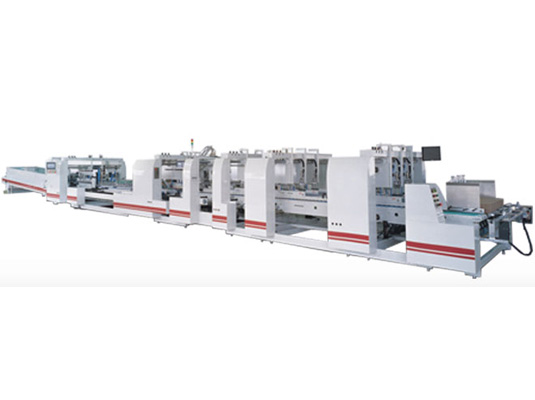

Folder Gluer SCM 1450С, 1600С, 1800С, 2200С

Strong structure for big size boxes, max. speed upto 250m/min

Product details

Advantage

- The main machine is controlled by human-computer interface, connected with remote controller, ensures easy adjustment and operation.

- All transmission belts of the lower panels are wrapped around externally, no need to unload the transmission shaft during replacing belts.

- The upper pressing bars can be set via micro-adjust depending on different paper thickness.

- The stable design ensures machine without shaking during high speed operation.

- The plate is run by electricity which can be easily done for changing the different size boxes.

- Standard machine can be advanced by adding optional unit like Regulator, Pre-folder, 4 and 6 corner attachment, Panel movement by motorization to achieve highest efficiency.

- Shaft-less drive is taken as main drive(Intelligent computing and tracking), and the drive makes lower noise.

- The speed of main machine and pressing part is controlled by inverter, and speed of main machine, feeder part and pressing part is adopted through the ratio link movement.

Specifications

| Model | SCM-1450II,1600II,1800II,2000II,2200II |

|---|---|

| Paper Range | cardboard; E,B,C,A flute corrugated board |

| Speed Range | max. 40-250m/min |

| Glue | emulsion type |

| Box Type | straight line; double wall; lock-bottom; optional 4 or 6 corner collapsible box; |

*Optional function: UV grinder + Squating device + Regulator + Pre-folder + Plasma treatment + Cold gluing gun system + 4 and 6 corner attachment + Panel movement by motorization + Digital position system

Feeder part:

With independent transmission at low noise, coordinating with front adjustable wheel, which ensures maximum capacity for feeding.

Feeding knife and left right fixing plate is adjusted up and down by pneumatic system easily.

Brush wheel to remove the powder or dust which increase the belt friction for smooth feeding.

Pre-folder part:

The adjustment for various box size is available.

The first creasing line 180degree and the third creasing line 135degree is easily made.

Three panel belt system for pre-folding.

Crash lock bottom part:

Depending on various size of crash lock bottom box, the separable upper pressing bars can be extended in length.

The hookers with high steel springs are excellent and stable for high speed operation.

Lower gluing part:

Lower gluing wheel by 2 section doctor blade to control the gluing volume, avoid glue swinging.

Lowe glue tank is easy to remove, clean and fix.

Movable glue tank for adding the emulsion cold glue easily.

Folding part:

Meet various adjustment, precisely fold blanks.

With front and back movable upper pressing bar, easy for special designed boxes with optional device.

With additional part, the three panel system can be changed to one panel for small size boxes.

Trombone part:

Transit the paper straight and stably to the pile.

Equipped with the electronic sensor to coordinate the conveyor speed with the speed of main machine for perfect collecting.

Counter type for spraying gun and kicker with anti pumping device.

Conveyor part:

The pressure is by air cylinder, adjust the pressure level independently.