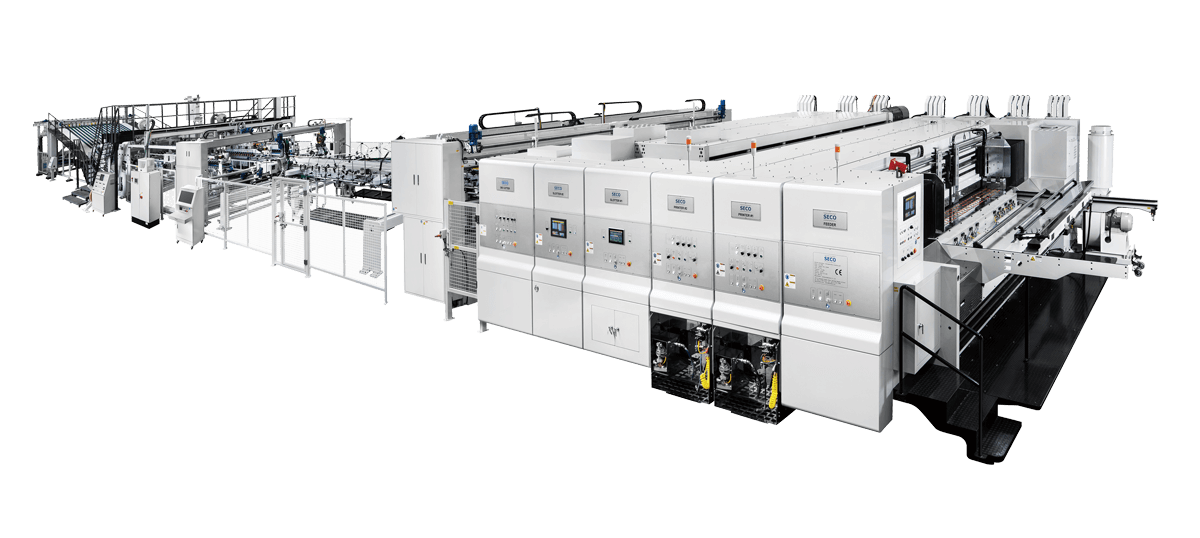

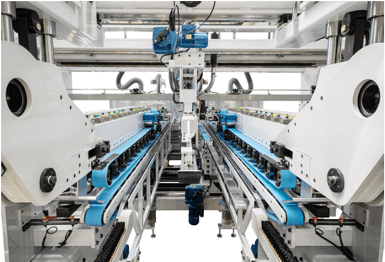

Flexo Folder Gluer Seco -

Flexo Folder Gluer is a flexo press supplied with in-line operations. In-line operations are applications other than printing that are performed on other equipment that has been combined with the press. SECO Flexo Folder Gluer is a complete inline equipment to print, shape, fold and, glue the corrugated boards to make boxes automatically set by computer with a self-diagnostic system.

Manufacturer Seco

Product details

.png)

FEEDER

- Automatic Settings for job change

- Easy replaceable tread wheel

- Anti-Static Dust Removal System

- SUN Automation(USA) Feeder adopted

- AC Vector Motor & Vector Inverter controller

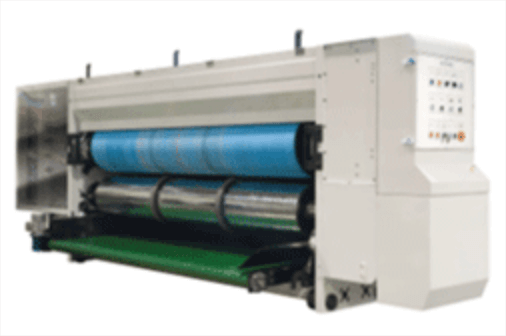

PRINTER

- Top or Bottom Printing

- Ceramic Anilox Roll

- Vacuum Transfer

- Automatic Settings for Zero point, Impress, Anilox, Damper and Washing

- Special surface treated transport wheel

- Chamber Doctor Blade : TRESU(Optional)

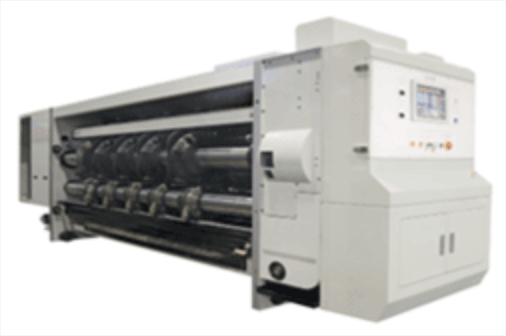

SLOTTER

- Accurate and precise setting position by LM

- Pre-creasing by Steel rules or Rubber rules

- Slitting knife : DUAL

- Big diameter of main-creasing rolls for effective creasing performance

- Robust structure to sustain the heave duty of high speed production

- Board is firmly hold during the slotting

- Isolated CREASER Unit(Optional)

DIECUTTER

- Conveyor for Scrap

- Automatic setting for Die cutting roll, Anvil Roll and Pull roll

- Dual Brake system, ANTI-Pratial wearing movement

- Anvil Grinding System(Optional)

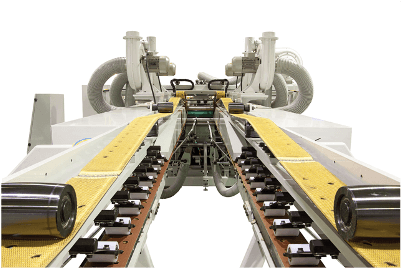

FOLDER GLUER

- Top or Bottom Folding

- Vacuum assisted folding belts equipped with suction chamber and pressure wheel

- Jam detection sensors and automatic stop system

- Valco / Copar jet glue system

- Adjustable glue flap

SQUARING DEVICE

- 4 sets of tail edge squaring belt

- 14 sets of air cylinder stopper at lead edge

- Automatic belt gap control from both direction (Top/Bottom)

- Independent servo-driven transport belt

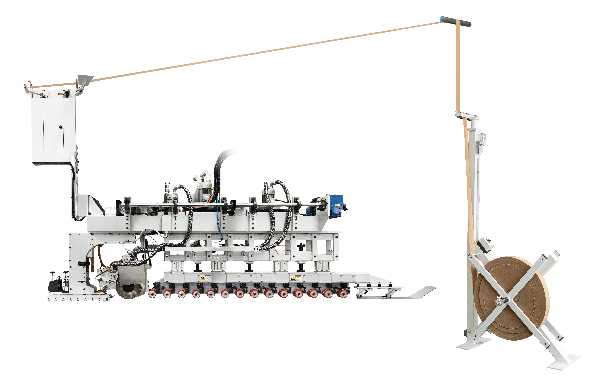

TAPING DEVICE

- Squaring unit exit of Seco Folder

- Below taper-wheel, 2 lines of height-adjustable roller

- Transportation and guidance of folded box by sandwich belt

- Automatic setting of sandwich belts

- Adjustable sandwich belt pressure

- Synchronized speed with the folder to avoid case braking

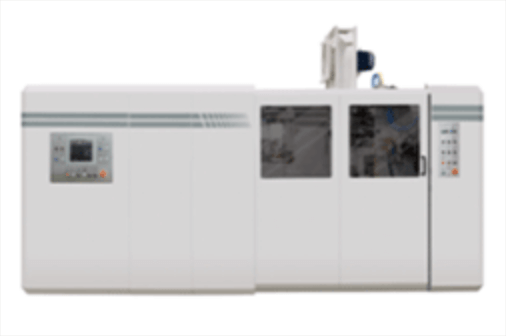

SINGLE STAGE TOP COUNTER EJECTOR

- Single stage construction

- Automatic lateral unit position setting

- Bundle compression device with air blow adjusting device

- Preset sheet counting

- Stable operation of Elevator thanks to AC Servo motor

- Simplified operation mechanism of Press Bar and Ledge by compressed air

- Fine adjustment of Feeder, Printer, Slotter, Die Cutter on 12” Touch screen panel

- Economical energy consumption

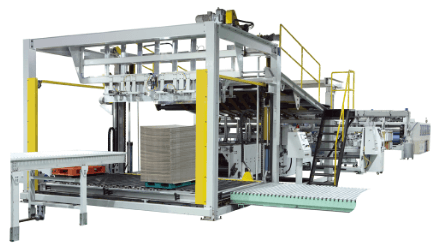

DOWN STACKER

- Squaring System

- Sheets in pile discharged by conveyor roller

- Counted bundle height: Max 2,000mm

- Full width stacker for max. unfolded sheet 5,000 mm

.png)

COMPUTER SYSTEM (CNC SYSTEM)

- 17” Main Touch Screen Panel at 3 Units

- Remote control feature: All units’ setting can be controlled from any touch screen

- Ethernet communication protocol between the units: fast, precise and stable setting

- Remote Customer Service via internet

- Job data saving and management

- Possible to interface with Factory Production Control System(Protocol open)

Contact form